Protect against leaks of corrosive or hazardous fluids from primary piping.

We offer two dual containment systems. Type I and Type II containment systems provide the added protection of a containment pipe. Type II offers additional pipe integrity utilizing custom end seals.

Dual containment systems I and II are compatible with leak detection systems. Custom monitoring stations can be designed as required throughout the piping system.

Our systems have proven to provide years of leak-free and worry-free service for our customers in environmentally sensitive areas inside and out of a plant.

Get in touch to learn more.

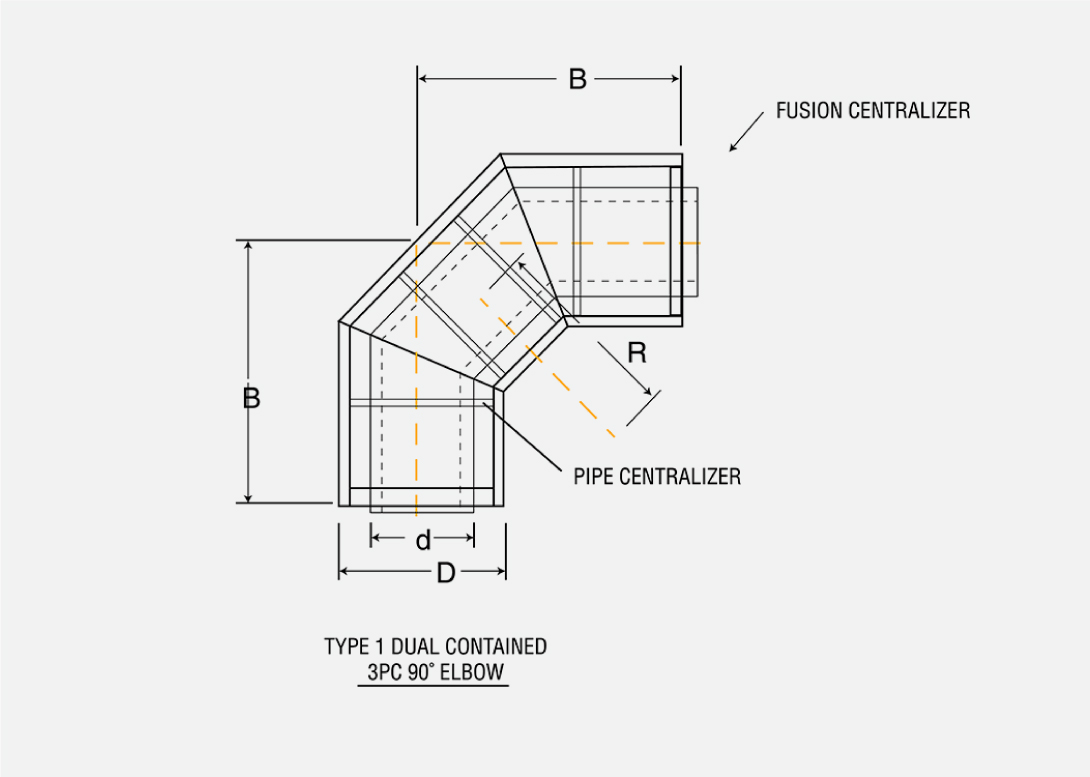

Type I

Features Type I containment systems include:

- Simultaneous heat fusion during joining to insure weld integrity

- Maintains consistent centralization of the carrier pipe within the containment pipe

- All pipe sections and fittings have full production traceability

- Handles all temperatures and pressures consistent with HDPE

- Monolithic system once installed

- Compatible with tracing wire

- Extrusion welded end plates connects both carrier and containment pipes

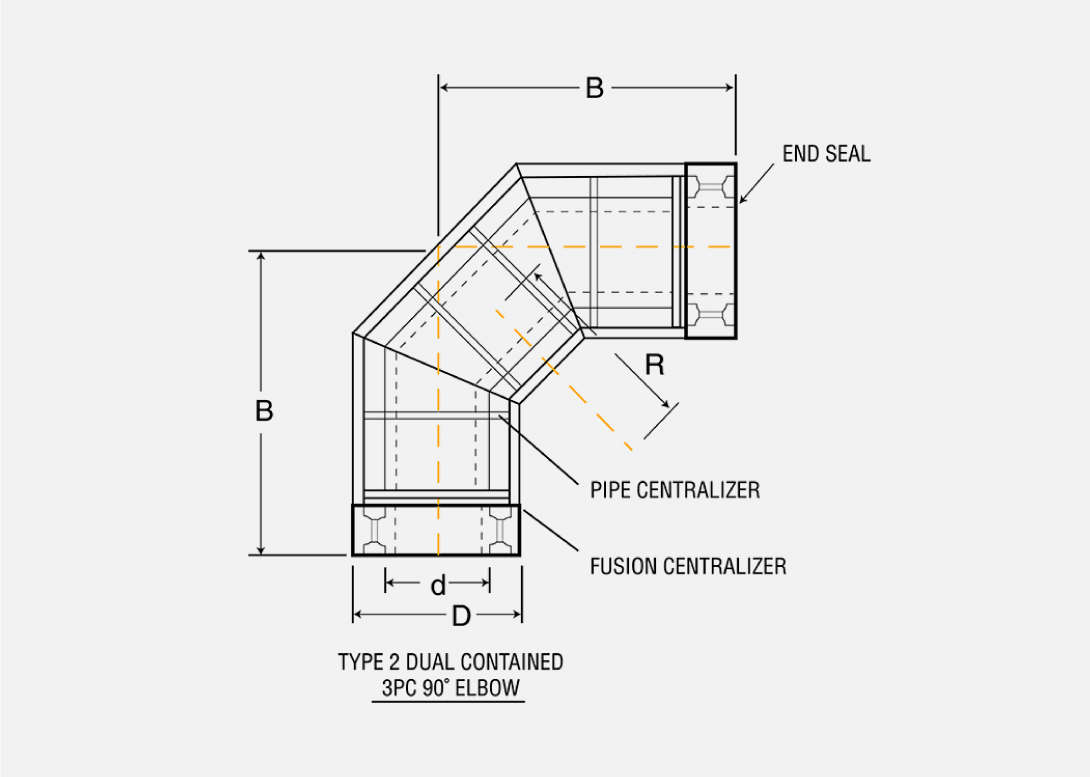

Type II

Features Type II containment systems include:

- Simultaneous heat fusion during joining to insure weld integrity

- Maintains consistent centralization of the carrier pipe within the containment pipe

- All pipe sections and fittings have full production traceability

- Handles all temperatures and pressures consistent with HDPE

- Monolithic system once installed

- Compatible with tracing wire

- Custom milled end seals fusion welded to carrier and containment pipe