Your Challenges. Our Connections.

When you partner with Ferguson Industrial, you benefit from all of our partnerships.

Between our deeply rooted manufacturer relationships and our industrial MRO, there’s no obstacle we can’t overcome together.

We maintain close, long-standing relationships with our customers. As a result, we know their industrial MRO needs as well as they do. Furthermore, we cultivate strong partnerships with Approved Manufacturers in order to have a quick response and to fulfill those needs with trusted products.

Ferguson Industrial does what it takes for every customer.

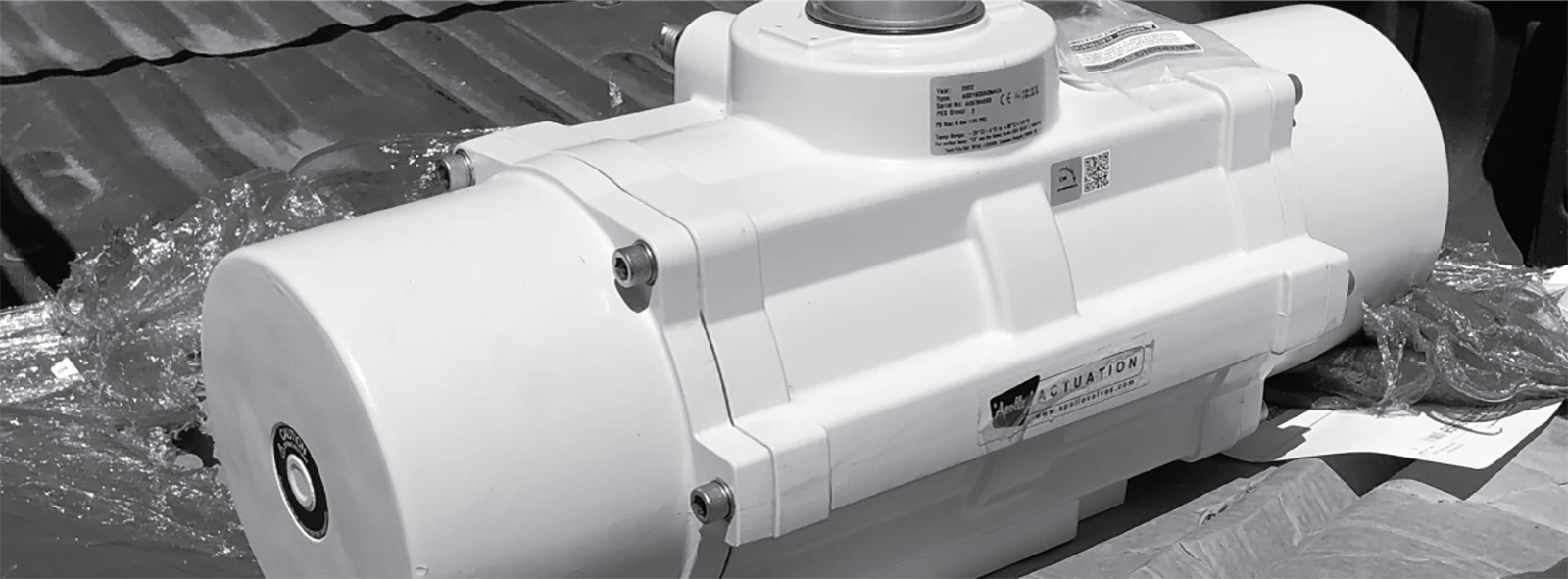

A rolling steel mill in southern Indiana got into a jam when an actuator suffering from corrosive wear-and-tear broke down. The break impacted a critical line in a vital area of their operation. As a result, the plant suffered a serious slowdown.

Since we’d collaborated with this customer for two decades, our associate knew exactly which actuator and mounting bracket were required when the call came in. The mounting bracket needed to be customized to fit a 20″ butterfly valve. Through a third-party partnership, we got to work manufacturing the specialized product

Our associate also identified an opportunity to improve performance by implementing a larger actuator. Facing a two-week lead time on the new actuator from the manufacturer, our experts tapped into our extensive partnership network. As a result, we found one locally that shipped the piece much faster.

When the order was fulfilled, Apollo Valves, our Approved Manufacturer partner couldn’t guarantee a delivery window. So we drove to the truck line terminal ourselves to pick it up and hand-deliver it to the customer.

Even with the need for custom manufacturing, our expertise, connections, and willingness to go the extra mile got the steel mill back to full strength in less than two weeks after the initial break.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.