Fast Delivery & Installation Of Access Platforms For A Remote Oil & Gas Plant

Ferguson Industrial acts fast to deliver and install ErectaStep access platforms and stairs. With in-stock products, intuitive design software, and eager associates, the OSHA-compliant metal stairs and platforms were installed within 72 hours - saving the plant millions in lost revenue.

Download Fast Delivery & Installation Of Access Platforms For A Remote Oil Gas Plant

PRODUCT USED

OSHA-compliant ErectaStep modular access platforms and stairs

CHALLENGE

Approximately 400 tripping hazards were discovered during a site risk assessment, preventing the plant from going into operation.

What effective solutions for tripping hazard remediation did we implement?

Using locally stocked products, our associate custom-configured, delivered and helped install a comprehensive OSHA-compliant access system to mitigate the hazards within 72 hours.

KEY RESULT

Ferguson Industrial associates expedited on-site delivery with minimal lead time. As a result, the plant saved $1.7 million per day in lost operating revenue.

PROJECT SUMMARY

BACKGROUND

Midland, Texas, is an isolated location, nestled amid some of the nation’s least populated stretches of land. It is hours away from any major city. Their economy—like most population centers in the Permian Basin—relies heavily on the oil, gas, and refining industries.

CHALLENGE

A pre-operational risk assessment identified approximately 400 trip-and-fall hazards. These included areas where the plant’s employees would have to step over dike walls and wires or stand on pipe to be able to operate valves. The assessed risks prevented the plant from entering operation, resulting in $1.7 million in lost revenue per day of downtime.

SOLUTION

The plant contacted our local product experts to address the safety concerns. Our associate conducted an on-site review and identified ErectaStep modular stairs and work platforms as a viable solution.

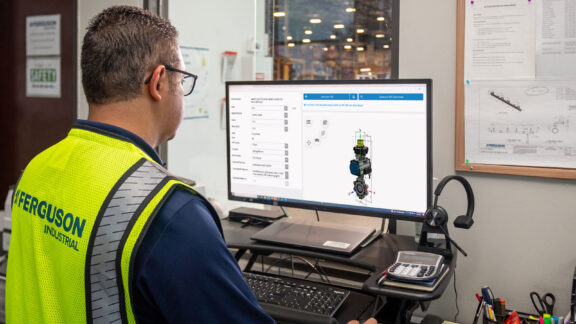

Using ErectaStep’s intuitive design software, the associate configured an OSHA-compliant access system in real time during the site visit.

The proposed system combined ErectaStep’s five standard modular components to provide walkways, elevation changes, and workspaces that aligned with the plant’s unique needs and stated safety concerns. Because of the plant’s remote location, obtaining an equivalent access system from a competitor could have prolonged downtime for weeks.

But as a stocking distributor of ErectaStep, we had enough product in stock at our Midland location to cover the full scope of the project’s material needs in a single expedited delivery.

Once the product arrived at the plant, our team provided on-site assistance to install the system correctly, safely, and efficiently.

THE FERGUSON INDUSTRIAL DIFFERENCE

Because of our close partnership with ErectaStep, our team fulfilled the order for OSHA-compliant access platforms and stairs. From the initial call and on-site configuration to delivery and installation, the access system was ready in only 72 hours. Our national footprint and commitment to maintaining relationships with Approved Manufacturers enables us to provide high-quality solutions wherever necessary with as little lead time as possible.

ABOUT ERECTASTEP ACCESS PLATFORMS

ErectaStep’s line of industrial metal stairs and work platforms eliminates the need for custom fabrication. With its patented modular design, an ErectaStep system can be configured in real-time to provide safe access for maintenance and crossover applications. Each modular component is durable and made with high-quality materials that withstand the harsh environments of industrial facilities. All the while, they maximize product reliability.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.