How to Ensure Quality Control for Industrial Suppliers

Ask your supplier the right questions

Whenever industrial companies search for a Pipe, Valve, and Fitting (PVF) supplier, they often don’t ask enough questions about a prospective supplier’s quality program. Sometimes they merely ask a single question: “Do you have a quality program?” with a box to check, yes or no.

The consequences of product failure in your industrial plant can be catastrophic. Furthermore, rework due to a failed product wastes manpower, time, and money. Consequently, selecting a low-price supplier without a robust quality program could in fact cost you more.

Vet Potential Industrial Suppliers and Save

Industrial operations require predictability and minimal disruption to the work process, which, in turn, depend on products that perform reliably. This is why quality control for industrial suppliers is vital. Many factors can negatively impact product quality, so you must be diligent in vetting potential suppliers that are worthy of becoming your long-term partners. To find the right supplier, you must ask them to do more than simply check a box. You have to dig deeper and ask the right questions—tough questions—that demonstrate a supplier not only deserves your trust but also delivers what you deserve most: Peace of mind.

COST DOES NOT EQUAL PRICE

When an industrial company wants to select a Pipe, Valve, and Fitting (PVF) or MRO partner, their supply chain professionals usually send a potential supplier a Request for Proposal or Quote (RFP/Q). This typically includes a request for information or a questionnaire that attempts to ascertain the supplier’s qualifications. For example, questions about the size of the company, years in business, service capacity, and other relevant capabilities.

Somewhere there might be a query about quality control for industrial suppliers. Unfortunately, it can be as simple as a single question along the lines of “Do you have a quality program, yes or no?” – a simple checked box.

Honestly, how often do your suppliers answer “No” to that question? Even if their quality program might consist of one person with a caliper, they can check the “Yes” box.

Questions to ask a potential industrial supplier.

If you want to be sure you have the best partner as a supplier, it starts with verification of the supplier’s quality control program. The RFP/Q process is long and costly, requiring many resources. When going through the process, intending to find the best supplier, you need to do whatever you can to validate the quality control for industrial suppliers. Get to know their processes and understand the value of the products and transactions you might receive from a supplier.

What is quality? Do you know it when you see it? It may be hard to define, but one thing is certain: Quality is more than just a checked box. It’s not vague or insubstantial. Quality is about meeting expectations and not wasting your time.

Above all, it’s about safety, repeatability, minimal disruption to work processes, and your bottom line.

Cost does not equal price.

Total Cost of Ownership (TCO) also includes the consequences of a product not performing as it should, including the costs related to safety and lost time. If there is an event, the actual cost of a $40 part might be $40 million.

How closely do you look at your quality control for industrial suppliers, and how often? What might you save—or lose—by not looking deeper into your supplier’s quality program? Quality has an enormous impact on TCO and your Return On Investment (ROI).

As a procurement officer, engineer, or Engineering- Procurement-Construction (EPC) contractor vetting a supplier, you need to look harder. A partner without a robust quality program might seem good on paper because of the price, but selecting them may actually be your most expensive option. Ask yourself, “What am I missing? Are there risks to my organization?” Asking the right questions will make your job easier, and will help protect the lives of the people working in or near your facility.

WHY QUALITY MATTERS

Your bottom line depends on the safe performance and service reliability of the products used in your operations. Predictability is crucial to your planning because it allows safe operation, saves you time and money, and promotes sustainable profitability. Invest in quality control for industrial suppliers.

You can’t have predictability without good quality control for industrial suppliers. This includes products that conform to specifications and minimal disruptions of the process. That’s why quality matters. Quality is defined by meeting specified requirements and attributes. It’s the foundation of stability for available inventory, predictable logistics, and on-time delivery. Put simply: Quality promotes everyday safety and performance.

Your safe, reliable, predictable, and profitable operation depends on the timely availability of products that conform to specified requirements. Product reliability promotes worker and community safety, good life cycle management, profitability, and retention of working capital. Products need to be delivered on time and in usable condition. Who has not felt the repercussions of a delayed shipment or a part that was mishandled? How many of these events could have been prevented by paying a little more attention to detail?

Rework Costs and Wasted Time

Quality is about time and money. Many customers are unaware of the TCO of a particular product, especially when you factor in the cost of rework and the time it wastes. Rework costs may be many multiples of the original cost of the product—not to mention the potential cost to injured workers, their families, and the community.

An ounce of prevention is worth a pound of cure

If you ever find yourself thinking, “Maybe the dollar I saved on that product that didn’t work should have been spent on a product that did”, then congratulations— you’ve come around to the right way of thinking. It’s also likely you’re thinking about ways you can improve your company’s procurement processes. The old adage “an ounce of prevention is worth a pound of cure” applies here. Rework costs are dead expenses and greater than normal transactional costs.

- Time can’t be reclaimed or stretched—it’s far more critical than many of the fluctuating variables of the supply chain.

- Rework wastes manpower, profits, and efficiency, and the disruption to your work processes is enormously costly.

Underperforming, nonconforming, and defective products cause untold safety and reliability problems. As a result, they cost U.S. industries hundreds of billions of dollars every year. The right supplier, however, values your time. They help you not to waste money, provide quality products and processes that prevent disruptions, and minimize negative impacts on availability, pricing, and service.

PRODUCT QUALITY AND HOW IT CAN GO WRONG

Product Failure

What are the results of a “product failure”? It’s always unplanned. It could be a financial cost – premature component replacement, reworking, or panic sourcing of new parts. Or a catastrophic event that compromises human life, community safety, the financial viability of your plant site, and your company’s reputation. The reality of product failure is that people can be injured or killed and companies destroyed. These are our families, friends, and communities—people depending upon your facility’s safe and profitable operation. For example, if a plant shuts down because of an incident, there’s a good chance it could be closed—gone forever. If a site is hanging by a financial thread and expenses are currently greater than profits, a serious incident could be financially catastrophic for the site and the community where it’s located. This brings to reality the importance of strict quality control for industrial suppliers.

A “Race to the Bottom”

Manufacturing is based on product specifications and tolerances, and many manufacturers tend to produce towards the minimum required to achieve marketability. Additionally, they’re always under pressure from purchasers to lower their prices. When their expenses rise, the vice squeezes tighter. At some point, they’ll try to reduce costs because they, too, wish to make money, after all. Competitors sometimes employ the strategy of taking market share with inferior or less expensive products. Suppliers also tend to gravitate towards the least expensive way to make a functional product within design limits. As a result, when products start retaking market share that cost less to manufacture, it starts a cycle of competitiveness that ends in a “race to the bottom”, which stops – hopefully – within industry-mandated specifications.

Regardless, the new product may not perform as well as the previous one. Your net profits could decrease when products you procure are at the lowest limits of conformity. The wear and tear of your services may require less robust products to be replaced more frequently, increasing your TCO.

Engineering and Manufacturing Competence

It’s not uncommon to find suppliers whose quality personnel don’t have adequate time for their duties or are pulled into other business-related duties. This leaves less experienced and less competent staff to manage the technical responsibilities. Consequently, it has adverse effects on product quality and causes compliance problems when product and/or test certificates are issued. During such times, a customer may depend on the supplier to do its own self-auditing. The bias inherent in this process is self-evident.

On the other hand, suppliers with engineering and manufacturing competence reflect have skilled and experienced staff. As a result, they embrace competent processes. Its processes, certifications, and accreditations speak to its cultural and managerial commitments, repeatability, and predictability. Quality is ingrained in their culture; its people own the processes and they understand the spirit of what you, the customer, are trying to do with your business. In conclusion, they have what it takes to help keep you safe and operate efficiently.

It’s All About People

Quality is, in fact, driven by people. It’s not a country, a flag, a banner, or a logo. Rather, it is a group of people who want to do the right thing for themselves and their customers. It’s a partnership demonstrated through trust and reliability. They want things to go as planned, for both of you and believe in quality from the top down. Furthermore, they have a firm management buy-in to attract and drive, talent, individual effort, and strong work ethics.

Sub-tier Suppliers

Very few manufacturers make every part for every product they produce. It’s an integrated world and every supplier needs good sub-tier suppliers for equipment, materials, semi-finished parts, and finished branded products. But if a manufacturer suddenly is forced to switch suppliers, or use a new one, they could see product quality plummet overnight. If an already compressed supply base shrinks even more, the supplier may find itself in a desperate situation.

- Find a new sub-tier supplier or

- Shut down.

This often leads to procurement from less reliable sources resulting in a loss of reliability that will eventually flow downstream to the customer. But the right supplier isn’t as affected by losing sub-tier suppliers. Why? Because it’s prepared: with an already-compiled, robust list of qualified suppliers. It doesn’t have to go to the “B-list”.

You, the customer, need to know if your supplier is monitoring its A-listers.

Unsuspecting suppliers and customers may receive transshipped and/or underperforming products. It’s the responsibility of the quality control program to evaluate how any changes to the supply chain might affect quality, because a loss in manufacturing quality may not immediately be detected by a customer.

SUPPLIER QUALITY

Logistics and Information

Your supplier should plan for and maintain redundancies in supply and logistics. It has extensive market knowledge because of its experience and intelligence gathering. This means it keeps up with what’s going on. Environmental, political, and economic barriers can suddenly remove sub-tier suppliers from the market whose products previously were available, reliable, and affordable. A good supplier is aware of how its suppliers are influenced by market forces and plans around potential shortages or interruptions in supply. They should be plugged into the changing global marketplace and share reliable information with you.

The digital era makes it easy to spread information– and disinformation. Rapid dissemination of false information that can’t be verified by non-experts creates false scares. A good supplier makes sure its information is always up-to-date, gathered and examined by experts, and verifies what you may have heard through the grapevine in order to quash false rumors.

Scalability – Does size matter when it comes to quality control for industrial suppliers?

To have a robust quality program takes considerable resources. If a prospective supplier’s program is not robust enough, it should be a warning sign. The PVF industry is global. Today, a good supplier must have the resources to travel around the world and perform the audits, interviews, and investigative work that may be necessary to maintain a vetted, backstopped supply base.

Suppliers should be able to show you with whom business is transacted as well as data to support why you should trust the products being supplied to you. Whatever their size, your supplier should be able to scale its products and services to its customer’s locations and operations. Your supplier should be able to identify multiple reliable resources, monitor the markets for potential disruptions, and minimize the effects on its customers. They should be a market expert that forecasts trends and responds rather than merely react. In comparison, they shouldn’t simply be along for the ride with you, hanging on and hoping for the best. In addition, they should be financially healthy. Customers should obtain a Dun & Bradstreet report and any other financial data available on all potential suppliers. Furthermore, consider using reputable business look-up services that contribute data about a company’s ethics and compliance.

Vetted Suppliers – Approved Manufacturers List (AML)

Quality begins with a supplier having competent people and processes for assessing its suppliers and products. It’s bolstered through effective monitoring of product quality and implementation of corrective actions. Such actions include the suspensions and disapproval of supplier products. It’s imperative that a supplier maintains a dynamic AML that demonstrates supplier qualification and monitoring and product diversity that’s appropriate for your business needs and scale of operations.

A good supplier’s AML, if well maintained, provides immense benefits to you. By the details it contains and the frequency of its updates, an AML shows you whether a supplier has developed adequate, good resources and is maintaining positive business partnerships with them. An established AML is expensive to maintain, but its importance cannot be overstated. It requires the appropriate resources and its own quality management that must be separate from the supplier’s commercial influences.

CONCLUSION

Finding an established supplier with a comprehensive quality program is crucial to any industry. Unplanned disruptions are costly, but quality processes and diligent monitoring of suppliers prevent many disruptions. In the final analysis, the best value a supplier can provide to a customer is a robust and integrated quality assurance program that promotes a culture of quality from the top down. A good supplier is concerned about safety, decreasing your TCO, and improving your ROI and bottom line.

Here are five questions you should ask your industrial supplier about quality control:

- Is your company registered by an internationally recognized registrar to ISO 9001 or another recognized Quality Management System? If so, please include a copy.

- Does your company have formal policies and procedures to: a) identify qualified suppliers; b) prohibit purchasing, receipt, and/or sale of disapproved products; c) identify suppliers of nonconforming products; d) require corrective actions from suppliers? If so, please include copies.

- Does your company have documented, controlled procedures and work instructions for the qualification and auditing of its suppliers, as well as for the sampling, inspection, and testing of products from those suppliers? If so, please include a copy.

- Does your company employ competent, dedicated associates who perform the sampling, inspection, and testing of supplied products? If so, please provide an organizational chart of your QA Department.

- Does your company have the capability to validate specified product markings, finish, dimensions, and specified material properties (e.g., chemistry, mechanical properties, corrosion resistance)? If so, please list where these processes are performed.

These questions focus on qualifications, technical data, performance metrics, competence, training, traceability, continuous improvement, and transparency – factors that prove a supplier deserves your trust. Always remember: Trust, but verify.

The best value is not necessarily the lowest price.

TCO and ROI always must be considered. It might be time to rethink another old saying, “There’s good, fast, and cheap – you can have two.” Quality is free. It helps reduce your rework costs and TCO, and it promotes safety, reliability, and profitability. TCO is based on premium performance. It’s a balance of quality, service, and price, reflecting ever-changing needs and conditions. To find this balance you need to find a supplier that offers a superior quality program, respects its customers, and delivers on its promises. This allows you to focus on higher-value and strategic tasks. Picking the right supplier with a robust QA program allows you to spend more time where you’d prefer, rather than dealing with issues arising out of product nonperformance.

Ask a potential or existing supplier the tough questions. Don’t just ask them to check a box. Dig deeper. Finding the right supplier with which you can create a lasting relationship – a partnership built on trust – will give you peace of mind.

To learn more about how to find a quality supplier, click here to contact your local Ferguson Industrial associate to learn more about our quality assurance program.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

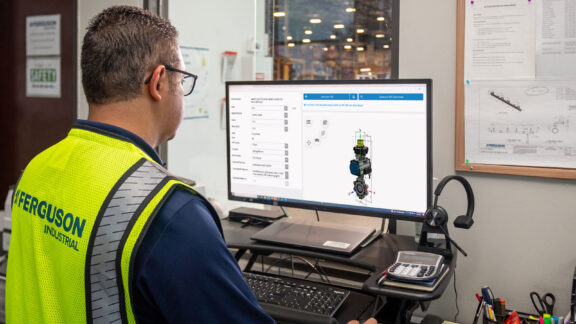

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.