A clear path to extend product life and improve your bottom line

Our technical expertise offers a clear path to resolution for any situation.

When a product weakness becomes so commonplace that failure is expected, it’s time to reassess that product’s role in your facility. This is especially true when repeated problems impact your bottom line. Don’t settle for less than the best.

At Ferguson Industrial, we hold our products to a higher standard. We leverage our national reach, custom design capabilities, and our team of technical experts. As a result, we supply products that empower the success of industrial facilities at the local level and improve your bottom line.

That is why when an energy company grew tired of replacing their severe service control valves twice yearly, they turned to us to find an alternative. We discovered flaws in the valve design and jumped into action to find a better solution

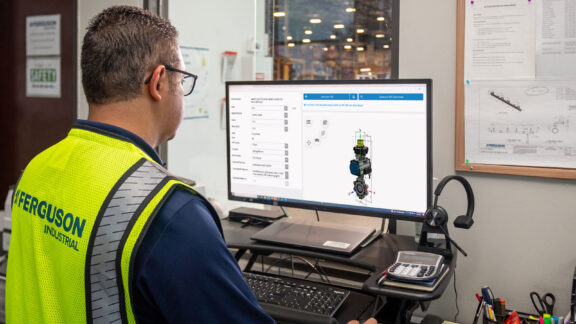

If you are in the process of designing a valve, use our free, online valve configurator to ensure your assembly is completed to the necessary specifications.

Our commitment to quality, value, and service saved the oil refinery company $488,000 in valve replacement costs over five years.

To address the expensive, reoccurring issue, our team worked with valve manufacturer UnionTech. Together we made significant design changes to the valve internals. Then we introduced and developed a metal seated ball valve program. This solution eliminated the damaging steam leak that was previously occurring. As a result of our proactive solutions, the lifespan of the valve increased from six months to more than two years. Our experts also designed the valve to make it compatible with existing brackets, couplings, and actuators. Due to this extra effort, our customer did not need to purchase new actuators to install the upgraded valve. To top it off, we provided the enhanced premium valve at the same price point as the original valve.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.